Introduce:

Hexagonal screws are widely used in various industries due to their stability and high torque capabilities. These vital fasteners connect countless products together, from machinery and vehicles to appliances and electronics. While the quality of the hex screw itself is important, we cannot ignore the critical role of its mold in ensuring precision and efficiency during the production process. In this blog, we’ll explore the latest advances in hex screw mold technology, focusing on how these innovative molds are revolutionizing fastener production.

1. Improve accuracy and consistency:

Screw molds have undergone significant changes over the years, improving the accuracy and consistency of fastener manufacturing. These molds are precisely designed and machined using advanced computer numerical control (CNC) technology, ensuring every screw produced meets precise specifications. This level of accuracy not only ensures fastener reliability, but also saves time and resources spent correcting inconsistencies.

2. Rapid prototyping:

With the development of modern manufacturing technologies such as 3D printing, the mold production process has become faster and more cost-effective. Hex screw molds can be created in hours instead of days or weeks, allowing for faster development of prototypes for testing and evaluation. This rapid prototyping facilitates timely iteration and improvements, allowing new and enhanced screw designs to get to market faster.

3. Material innovation:

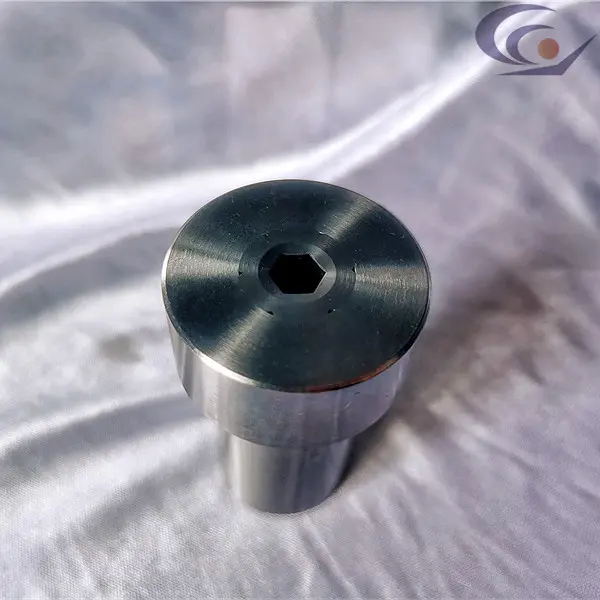

The materials used in hex screw molds play a vital role in determining their lifespan and performance. Recently, significant advances in materials science have revolutionized the quality of molds. Titanium and stainless steel alloys are now the preferred choice due to their high durability, wear resistance and corrosion resistance. These materials not only ensure the longevity of the mold, but also help improve the overall quality and reliability of the hex screws produced.

4. Customization and flexibility:

To meet the diverse needs of various industries, hex screw mold manufacturers are now offering greater customization and flexibility in their products. They can create molds that meet specific design requirements, including unique screw head shapes or thread types. This level of customization allows manufacturers to produce fasteners suited to their specific applications, thereby improving the overall quality and efficiency of the final product.

5. Automation and increased productivity:

Automation has become an important trend in the manufacturing industry, and hexagonal screw mold production is no exception. The integration of robotics and advanced machinery streamlines manufacturing processes and increases productivity and efficiency. Automated mold production reduces human error, shortens production cycles, and minimizes downtime during mold changes. These advancements ultimately lower production costs and increase overall profitability.

In conclusion:

Advances in hex screw mold technology have revolutionized the way fasteners are manufactured. The precision, quality, and customization options offered by modern molds have significantly improved the reliability and functionality of hex screws, resulting in better end products for various industries. As materials innovation, rapid prototyping, and automation continue to advance, we expect hex screw molds to be further improved, ultimately shaping the future of fastener production.

Post time: Sep-25-2023