Introduction:

In wire manufacturing, precision and efficiency are crucial. One particular technology that plays a key role in achieving these properties is the square drawing die. This innovative tool revolutionizes the wire drawing process, allowing manufacturers to produce wire with exceptional precision and consistency. In this blog, we’ll take an in-depth look at how square wire drawing dies work, revealing their significant contribution to the wire industry.

Brushing Art:

Wire drawing is a process that reduces the diameter of wire by pulling it through a die, usually made of tungsten carbide. This transformation is achieved by subjecting the wire to significant tensile forces, resulting in elongation and reduction in diameter. However, traditional mold designs often result in inconsistent wire shapes and require frequent replacement due to wear. That’s where square wire drawing dies come in, proposing a game-changing solution.

Unleashing precision using a square drawing die:

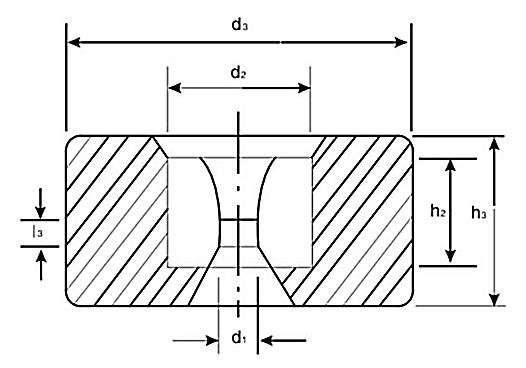

Unlike traditional round dies, square wire drawing dies have square holes for the wire to pass through. This unique design ensures even contact with the wire surface, resulting in superior molding and reduced excessive deformation. The square shape eliminates eccentricity issues common in round molds. Square wire drawing dies therefore guarantee superior precision and consistency in the production of wire of various sizes and dimensions.

Efficiency amplification:

The square wire drawing die not only brings precision but also improves the efficiency of the wire drawing process. Square dies have a higher fill factor, which means more wire can be drawn simultaneously compared to round dies. This increases productivity, reduces production time and ultimately saves costs for wire manufacturers. Additionally, the reduced distortion and improved wire surface finish achieved through the square die design minimizes the need for additional wire processing such as grinding or polishing. As a result, overall production time and costs are further reduced.

Conclusion:

Square wire drawing dies undoubtedly bring precision and efficiency to new heights, revolutionizing the wire manufacturing industry. Its unique square shape ensures uniformity, accuracy and consistency in wire production while increasing productivity. As wire manufacturers continue to seek innovation, square wire drawing dies remain a trusted companion in their pursuit of excellence.

Post time: Oct-27-2023