Introduce:

In the wire manufacturing industry, the use of carbon wire drawing dies is critical to achieving accurate and consistent wire diameters. Drawing dies play an important role in the wire production process, transforming rough wire into smooth and uniform wire. In this blog, we delve into the fascinating world of carbon wire drawing dies, exploring their construction, materials and the critical role they play in the wire industry.

Learn about carbon wire drawing molds:

Carbon drawing dies are designed to withstand the extreme pressures and temperatures involved in the drawing process. These dies work by continuously reducing the diameter of the wire through a series of drawing steps until the desired diameter is reached. These molds are used in a variety of industries, including automotive, aerospace, electrical and jewelry, where precise wire dimensions are critical.

Construction and Materials:

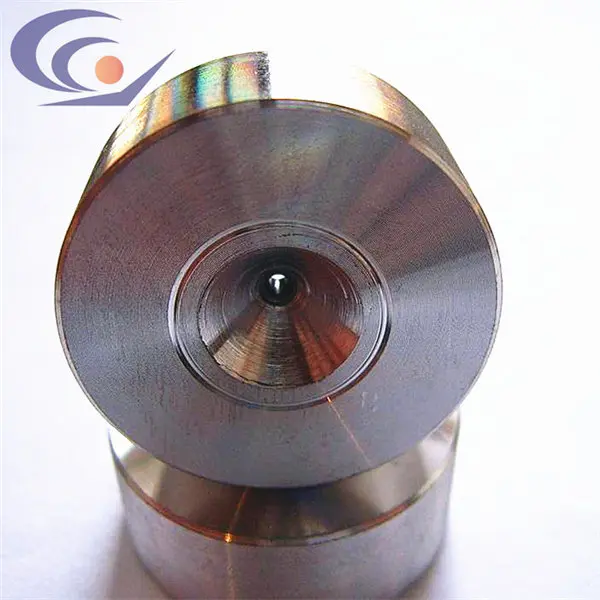

Carbon wire drawing dies are usually made of high-quality industrial diamond or tungsten carbide. These materials offer exceptional hardness, abrasion resistance and durability, allowing them to withstand the rigors of the drawing process. Diamond and carbide blanks are carefully shaped and polished into molds to ensure smooth and accurate wire reduction.

Drawing process:

The wire drawing process begins with selecting a suitable carbon wire drawing die, which is selected based on the desired wire diameter. The wire is then fed into a series of dies with progressively smaller holes. As the wire passes through each die, it undergoes considerable elongation and diameter reduction until it reaches the target size.

Importance in the wire manufacturing industry:

Carbon wire drawing dies are an indispensable tool for wire manufacturers for the following reasons:

1. Precision and Consistency: Wire drawing dies ensure precise wire diameter, allowing manufacturers to meet strict industry standards and customer specifications. Consistency in wire size is critical for seamless integration into a variety of end products.

2. Improve efficiency: Using high-quality wire drawing dies helps simplify the wire drawing process, thereby increasing productivity and reducing waste. This will save costs and improve profitability for wire manufacturers.

3. Durability and lifespan: Carbon wire drawing dies have a longer service life due to their inherent hardness and wear resistance, minimizing downtime and the need for frequent die replacements. This increases operational efficiency and reduces overall production costs.

4. Versatility: Carbon wire drawing dies are suitable for a variety of wire types, including copper, steel, aluminum and alloys. Their versatility makes them suitable for a wide range of applications in different industries.

In conclusion:

Carbon wire drawing dies play a pivotal role in the wire manufacturing industry, ensuring that the wire produced has precise dimensions, consistency, and durability. These molds are critical to achieving the wire diameters and shapes required for applications ranging from electrical wiring to jewelry making. The combination of craftsmanship, diamond or tungsten carbide materials, and advanced manufacturing techniques contributes to the success of wire rod manufacturers worldwide. As technology advances and wire specifications become more stringent, the continued development and improvement of carbon wire drawing dies remains critical to the future growth and success of the wire industry.

Post time: Sep-15-2023