Introduce:

In the field of precision engineering where accuracy and reliability are paramount, the importance of bolt screw moulds cannot be overstated. These carefully designed and crafted tools form the backbone of countless manufacturing processes, ensuring the production of high-quality bolts and screws that maintain structural integrity in various industries. This blog delves into the world of bolt and screw molds, exploring their complex nature and highlighting their critical role in precision engineering.

Learn about bolt and screw molds:

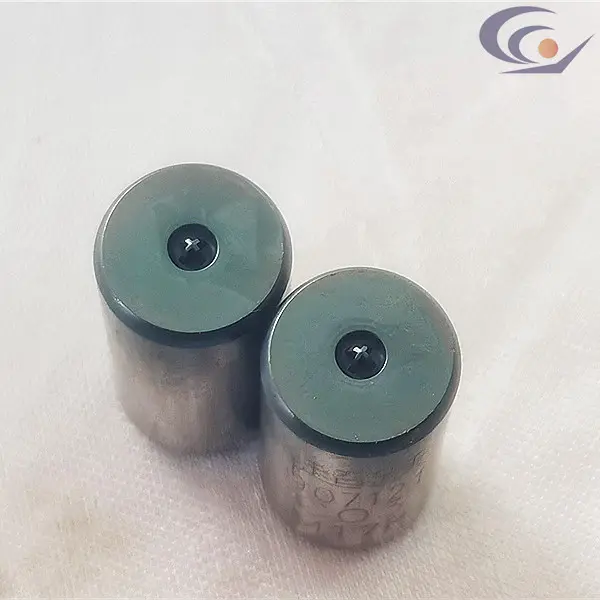

At first glance, a bolt or screw may look simple, but its production involves complex mechanical processes. Bolt screw moulds are used in injection molding technology and directly affect the shape, size and overall quality of the final product. These tools contain complex cavities and cores that determine the precise geometry of the fastener, ensuring its compatibility with a variety of applications.

Bolt and screw mold accuracy:

Manufacturing relies heavily on precision when producing bolts and screws. Small differences in dimensions or minor deviations from the desired design can compromise the integrity of the entire application. Bolt and screw molds must therefore be extremely precise, with tolerances often measured in microns. This is achieved through advanced computer-aided design (CAD) software and cutting-edge manufacturing technology, ensuring that each mold meets the most stringent accuracy standards.

Material selection for bolt screw moulds:

The choice of bolt and screw mold materials is critical as they should be able to withstand the high temperatures and pressures associated with the injection molding process. Typically, hardened steel alloys such as H13, D2 or S7 are preferred for their excellent durability and wear resistance. Moldmakers carefully machine these materials into complex shapes, ensuring the molds can withstand repeated production cycles while maintaining exacting standards.

The role of mold design:

The effectiveness of bolt screw moulds depends on careful design. Design engineers use a variety of techniques to optimize molds for efficient production. They consider factors such as gate design, runner systems, cooling channels and ejection mechanisms. The goal is to improve mold performance, minimize cycle times and reduce overall production costs. By employing state-of-the-art design methods, engineers can create perfect molds that streamline the manufacturing process.

Quality Assurance and Maintenance:

To ensure consistent high-quality bolt and screw production, strict quality control measures must be implemented throughout the entire life cycle of the mold. Regular inspection and maintenance procedures can help identify any progressive degradation or damage that may affect mold performance. If the mold becomes worn or damaged, it will need to be repaired or replaced promptly to maintain the accuracy and integrity of the final product.

In conclusion:

The fusion of precision engineering, material selection and careful design ultimately makes bolt screw moulds play their part. These complex tools are the unsung heroes responsible for producing the countless bolts and screws that maintain the structural integrity of our world. Their importance cannot be overstated, and as precision engineering continues to evolve, bolt screw moulds will remain at the forefront, ensuring reliability and durability for countless applications.

Post time: Oct-16-2023