Introduce:

In the field of metal processing, the quality and precision of components play a key role in determining the efficiency and longevity of various engineering applications. Hex drawing dies and thread rolling dies are two indispensable tools in this field, especially in industries where the production of screws, bolts and other threaded fasteners is crucial. This blog aims to delve into the evolution of wire drawing dies and shed light on the importance of wire rolling dies, particularly in the UK.

The evolution and functions of hexagonal drawing dies:

Hexagon wire drawing dies have come a long way from their initial development to now. Initially, simple pointed dies were used to reduce the cross-section of the wire. However, this process often results in uneven stress distribution and affects the accuracy of the final product. As the demand for thinner, more uniform wire grew, engineers developed hexagonal molds with precisely positioned and carefully designed entrance and exit angles. This innovation ensures a precise reduction in wire diameter, resulting in a smoother and more uniform wire that can be used in a variety of applications such as wires, cables and springs.

The importance of hexagonal drawing dies in the UK:

In the UK, where industry relies heavily on metalworking, hex drawing dies are an invaluable tool. From manufacturers in the automotive industry producing high-quality screws and connectors to the aerospace industry requiring precision manufactured components, the UK is home to numerous companies that rely on wire drawing molds to meet stringent requirements. The ability to consistently produce wire with precise dimensions, smooth surfaces, and high tensile strength is critical to these industries as it directly affects the performance and reliability of the final product. Therefore, the availability of reliable hexagonal wire drawing dies in the UK market is vital to maintaining the growth and competitiveness of these industries.

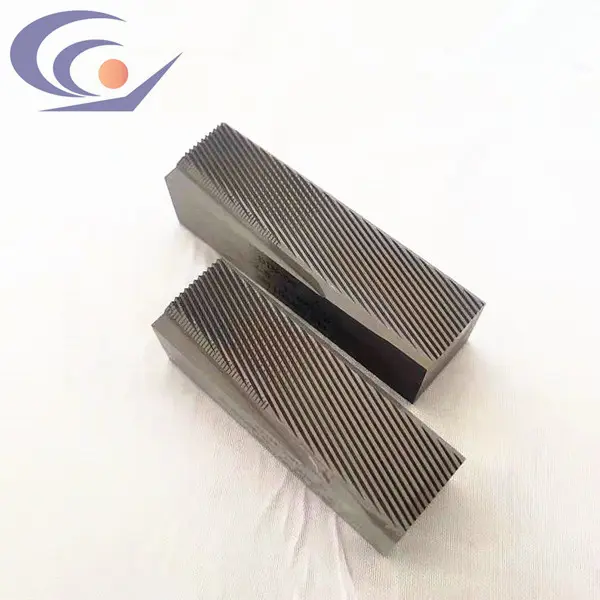

Thread rolling dies: the backbone of screw manufacturing:

In the field of manufacturing threaded fasteners, thread rolling dies play a pivotal role. The thread rolling process involves cold forming a hardened blank under high pressure to create the desired thread shape. This method provides superior thread strength, excellent uniformity and increased fatigue resistance compared to traditional thread cutting methods. Thread rolling dies are therefore the backbone of screw manufacturing, capable of producing high-quality threaded fasteners used in a wide range of industries.

The significance of thread rolling dies in the British market:

As the UK is a major player in the manufacturing and engineering sector, the importance of thread rolling dies cannot be overstated. The production of threaded fasteners is critical to many industries, from automotive parts and construction materials to aerospace applications. Thread rolling dies in the UK need to meet strict standards to ensure the reliability and quality of the final threaded fastener. This demand has created the opportunity for manufacturers and suppliers to meet the growing market demand and provide high quality thread rolling dies that can withstand the pressures and requirements of various industries within the UK.

In conclusion:

The evolution of hex drawing dies and the importance of thread rolling dies in the UK reveals the integral role these tools play in the metalworking industry. Precise wire diameter reduction through hex drawing dies and the production of high-quality threaded fasteners using thread rolling dies are critical to ensuring reliability, efficiency and performance in numerous engineering applications. As the UK continues to thrive in the manufacturing and engineering sectors, the availability and exceptional quality of these tools remains vital to continued growth and competitiveness in global markets.

Post time: Oct-11-2023