In manufacturing, the quality of the tools and equipment used can make a huge difference in the final product. The TC wire drawing die is an example of an important tool in the manufacturing industry. These dies are an important part of the drawing and forming process for a variety of materials, including metal, wire, and tubing. In this blog, we will explore the importance of using high-quality TC drawing dies and its impact on the entire manufacturing process.

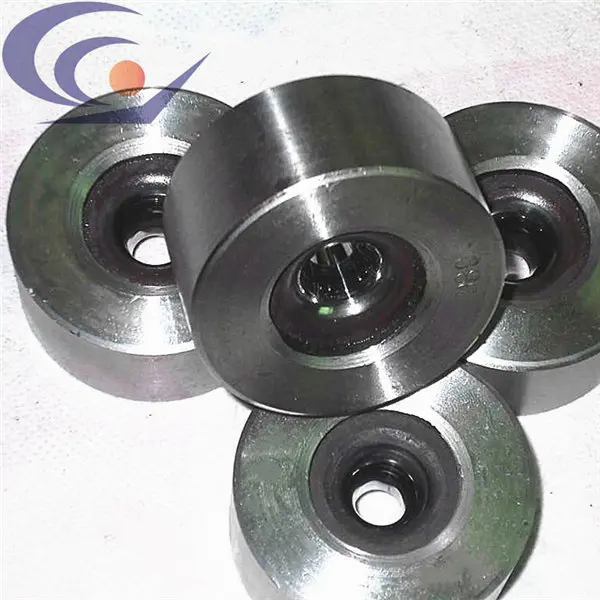

TC wire drawing dies, also known as tungsten carbide wire drawing dies, are widely used in the manufacturing industry due to their excellent hardness and wear resistance. This makes them ideally suited to the stringent requirements of stretching and forming materials. Using high-quality TC wire drawing dies enables a more efficient and cost-effective manufacturing process.

One of the main benefits of using high-quality TC drawing dies is the ability to produce precise and consistent results. When working with materials such as metal or wire, precision is critical to ensuring the final product meets the required specifications. A low-quality wire drawing die may cause irregularities and defects in the wire drawing material, resulting in substandard quality of the final product. On the other hand, high quality TC wire drawing dies are designed to maintain their shape and provide a uniform wire drawing process, resulting in a higher quality final product.

In addition to precision, high-quality TC wire drawing dies also have excellent wear resistance, allowing them to withstand the high friction and pressure during the wire drawing process. This extends the life of the mold, reduces the frequency of replacement and maintenance, and ultimately saves manufacturers time and money. Additionally, using high-quality molds can minimize downtime and production interruptions because they are less susceptible to premature wear and damage.

Another important aspect of using high-quality TC drawing dies is their impact on the overall efficiency of the manufacturing process. By delivering consistent and precise results, these molds can help manufacturers streamline operations and increase productivity. Additionally, the longevity of high-quality TC wire drawing dies means manufacturers can focus on their core production activities without having to constantly worry about die replacement and maintenance.

Also worth mentioning are the environmental benefits of using high-quality TC drawing dies. By reducing the frequency of mold changes and minimizing production interruptions, manufacturers can reduce overall energy consumption and waste generation. This contributes to a more sustainable manufacturing process and is in line with the industry’s growing focus on environmental responsibility.

In summary, high-quality TC drawing dies play a vital role in the manufacturing industry with precision, wear resistance, efficiency and environmental benefits. By investing in these high-quality tools, manufacturers can optimize their production processes and achieve superior results. As the demand for high-quality products continues to rise, the use of high-quality TC wire drawing dies undoubtedly remains the top priority for manufacturers to remain competitive in the global market.

Post time: Dec-12-2023