Introduce:

In manufacturing and precision engineering, the manufacture of complex components requires expertise in revolutionary tools and technologies. Among them, bolt dies, flat head screw dies, and self tapping screw dies play a pivotal role. These ingenious molds transformed manufacturing by producing high-quality, durable screws that facilitate seamless construction of various structures. In this blog post, we delve into the fascinating world of these mold types and discuss their importance in engineering excellence.

Bolt dies:

Bolt screw mould play an important role in the manufacturing process of bolts, which play a vital role in fastening various components in structures and machinery. These molds are engineered to produce screws with precise dimensions and surface finish, ensuring their seamless integration into any assembly process. Using bolt dies eliminates the need for hand fabrication, ensuring consistent quality with each manufactured piece.

Flat head screw mold:

Flat head screws are widely used in woodworking, metalworking and construction industries where flush surfaces are required. Flat Head Screw Dies are specially designed to shape screws with flat tops so that they are perfectly flush with the surface they are fastened to. These molds enable the production of standardized grub screws, ensuring their compatibility and interchangeability in different applications.

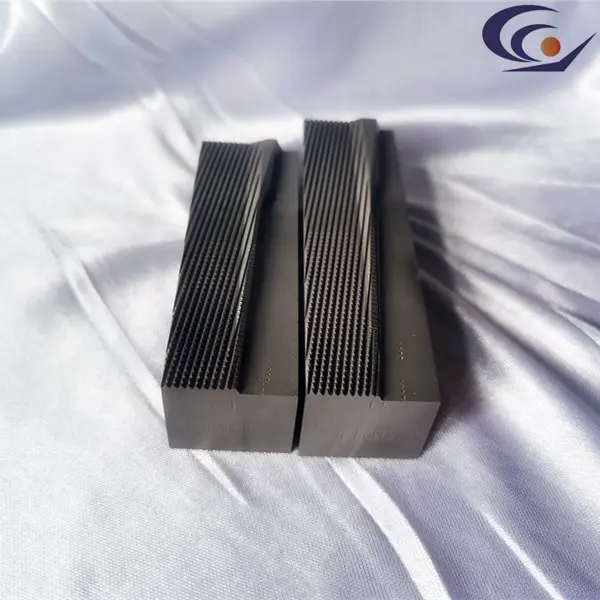

Self-tapping screw mold:

Self tapping screws are unique in their ability to self-drill without the need for pre-drilled holes. Self-tapping screw dies are designed to create screws with special threads that cut into the material they penetrate, creating a secure and long-lasting connection. These molds use advanced engineering to produce screws with exceptional durability, increasing manufacturing productivity and efficiency.

Precision Engineering: A Collaborative Effort:

The fabrication of bolt screw dies, grub screw dies and self-tapping screw dies requires a collaborative effort between skilled engineers, designers and manufacturers. Through meticulous craftsmanship, complex designs and specifications are transformed into precise molds. Advanced manufacturing techniques, including computer-aided design (CAD) and computer-aided manufacturing (CAM), ensure optimum precision and repeatability in screw production.

Quality assurance and future innovations:

To maintain the highest quality standards, continuous monitoring and testing is carried out during the manufacturing process. By adhering to strict guidelines and regulations, bolt screw dies, grub screw dies and self-tapping screw die producers ensure that each die produced meets the required specifications. In addition, continuous research and development drive innovation and improvement of these molds, enabling the manufacturing industry to evolve and meet the demands of modern engineering.

In conclusion:

Bolt screw mould, flat head screw mould and tapping screw mould are the unsung heroes behind the seamless integration of countless structures around the world. These exceptional molds exemplify the mastery of precision engineering, enabling the mass production of screws to exacting standards of quality and durability. The continuous development and utilization of these molds contributes to the development of the manufacturing industry, ensuring the continuous delivery of reliable, high-quality products. Bolt screw dies, grub screw dies and self-tapping screw dies propel us into the future through their innovation and excellence and precision engineering remains at the heart of our achievements.

Post time: Aug-25-2023