In the world of manufacturing, precision and accuracy are key factors that determine the success or failure of a product. Bolt dressing dies are one of the elements that play a key role in achieving precision in bolt manufacturing. This tool is the main tool in the production process and plays an important role in ensuring the quality and reliability of bolts. In this blog post, we’ll dive into the importance of bolt trimming dies in the manufacturing process and why it’s an indispensable tool for producing high-quality bolts.

Bolts are an important component in various industries including automotive, construction and aerospace. They are used to fasten and secure different parts, and their reliability is crucial to the safety and functionality of the products used. The bolt dressing mold is an important tool in bolt production as it is responsible for shaping and dressing the bolts. Bolts to meet specifications and tolerances.

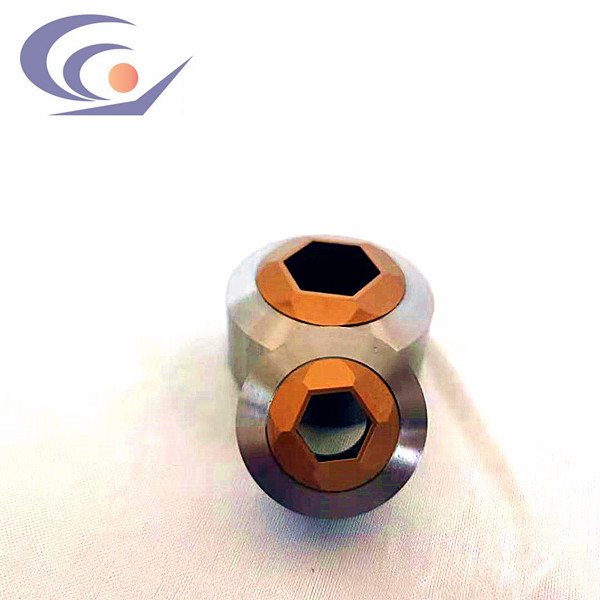

One of the key functions of a bolt trimming die is to ensure that bolts are cut to the correct length and that the cut edges are clean and free of defects. This is critical for the bolt to install and function properly in its intended application. Additionally, trimming dies help shape the bolt head to give it the desired shape and structure.

Another important aspect of bolt dressing dies is their role in maintaining bolt dimensional accuracy. By using precision technology and tooling, trimming dies ensure that bolts produced are consistent in size and shape and meet required standards and specifications. This level of accuracy is critical to the interchangeability and compatibility of bolts in a variety of applications.

Additionally, using bolt-trimmed molds helps minimize material waste and optimize the production process. By precisely cutting and forming bolts, trim molds ensure the manufacturing process is efficient and cost-effective. This is especially important in high-volume production, where every bit of optimization of materials and processes counts.

It is worth noting that the precision and accuracy of the dressing mold directly affects the quality and reliability of the bolts produced. Any deviation or imperfection in the cutting and forming process may result in the bolt being substandard and unfit for its intended use. That’s why manufacturers prioritize the use of high-quality trimming dies and invest in precision machining and production technology to ensure the consistent quality of their products.

In summary, the importance of bolt trimming molds in the manufacturing process cannot be overstated. This important tool plays a vital role in shaping, trimming and ensuring the precision and accuracy of bolts. Its impact on the quality, reliability and efficiency of bolt production makes it an indispensable component in manufacturing. By understanding the importance of bolt dressing molds, manufacturers can understand its role in producing high-quality bolts that meet the stringent requirements of various industries.

Post time: Dec-14-2023