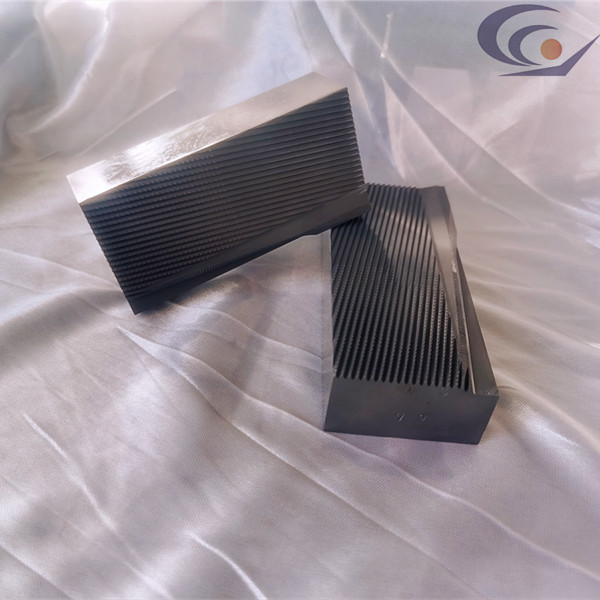

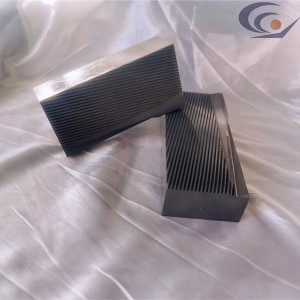

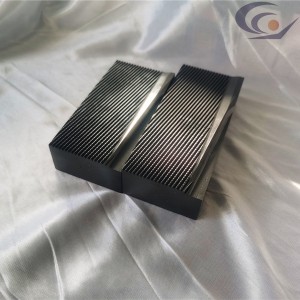

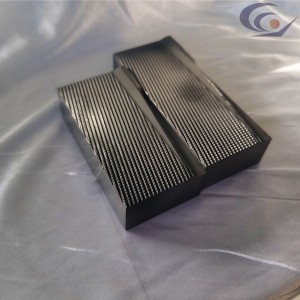

Umbrella Tooth Screw Threading Dies

Introduce:

In today’s fast-paced world, the importance of quality engineered components cannot be overstated. From automotive to manufacturing, every industry relies on precision and durable parts to ensure their products run efficiently. In this regard, it is crucial to highlight the significance of thread rolling dies for bevel screws. This blog explores how these specialized tools can improve the accuracy and durability of bevel screws, ensuring their effectiveness and longevity.

Advantages of thread rolling dies:

1. Enhance thread strength and precision:

Thread rolling mold is an important tool used in the manufacturing process of bevel screws. Unlike traditional cutting methods, thread rolling creates threads by applying pressure, moving and reshaping material. This technology eliminates any potential defects caused by the cutting process, resulting in stronger, more precise threads. Enhanced thread strength ensures that thread screws can withstand greater loads, minimizing the risk of failure or loosening.

2. Improve surface finish:

One of the main advantages of using thread rolling dies to make bevel screws is the superior surface finish they provide. Because die threads are formed by plastic deformation rather than cutting, the resulting threads are smoother and free of undesirable defects. This improved surface finish not only enhances the aesthetics of the screw, but also reduces friction and wear, improving functionality and extending the life of the product.

3. Higher production speed:

Thread rolling dies enable the production of bevel screws quickly and efficiently. Thread rolling can form threads in a single operation, significantly reducing manufacturing time compared to traditional cutting methods. Increased production speeds can increase yields, allowing manufacturers to meet higher requirements without compromising quality.

4. Extend tool life:

The use of thread rolling dies for bevel screws minimizes tool wear and extends the life of the dies. Because the threads are formed by pressure rather than cutting, there is limited contact between the mold and workpiece. This feature reduces the risk of wear, ultimately saving costs for manufacturers and ensuring consistent quality over the long term.

PRODUCT DESCRIPTION

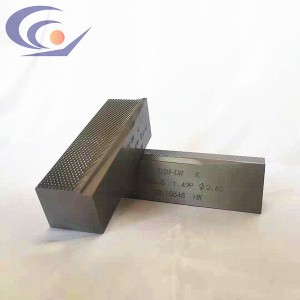

Thread rolling die is a conventional die for screw thread machine.It is made of HSS materials with carburizing treatment.It is used for producing thread of screw.

Our thread rolling die covered drywall screw,chipboard screw, self-drill screw,tapping screw,Wooden screw,machine screw,Furniture screw,Electronic screw,Combination screw,Blot,Nuts and other screws.

We can produced the accroding to standard or your screw drawing. And we can R&D accroding to your samples and customer’s request.

We have a strong technical team and used the computer control production process. Take advantage of latest softwares such as CAD/CAM, Solidworks, to perform the advanced technologies by senior engineers, professional heat treatment experts and know-how designers.To ensured the good quality of thread rolling die.

TECHNICAL SPECIFICATION

If you order the thread rolling die, please let me know the machine type,moulds size, wire diameter,screw type, teeth type,thread length,point type,outer diameter,inner diameter, and screw drawing .

diameter, and screw drawing .

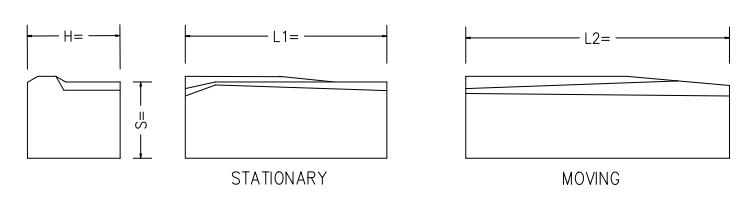

L1:Stationary dies length

L2:Moving dies length

S: Dies thickness

H: Dies width (Accroding to screws)

| Machine type |

S |

L1 |

L2 |

|

003 |

15 |

45 |

55 |

|

0# |

19 |

51 |

64 |

|

4R |

20 |

60 |

70 |

|

004 |

20 |

65 |

80 |

|

125 |

20 |

70/73 |

82/86 |

|

3/16 |

25 |

75/76 |

89/90 |

|

6R |

25 |

90 |

105 |

|

1/4 |

25 |

100 |

115 |

|

8R |

25 |

108 |

127 |

|

5/16 |

25 |

127 |

140 |

|

3/8 |

25 |

150 |

165 |

MATERIAL

DC53, M2, M42

We will accroding to your products,material,choosing good material and manufacturing technique, and will provide you with the best solution.

DELIVERY TIME

Standard Size:12 Working days

Customization:15 Working days

MOQ

Standard Size: 1 Set.

Customization: 2Sets

PACKING

Packed with antishock material and box, 1 set / box.

SAMPLES

We can offer 1-2Sets as samples to check the size and testing quality, but you should pay the cost and shipping cost.

PAYMENT METHOD:

Advance TT, T/T, Western Union, Paypal.

TRANSPORT DETAILS

Shipment by Air, by Train, by Sea, by TNT, DHL,SF-express.

ADVANTAGE

We have over 20 years of professional experience as a manufacturer of thread roling die.

Our price is reasonable and keep best quality for every clients.

We can make Form A, Form E, CO.